Computer vision models to automate visual inspection tasks using deep learning models

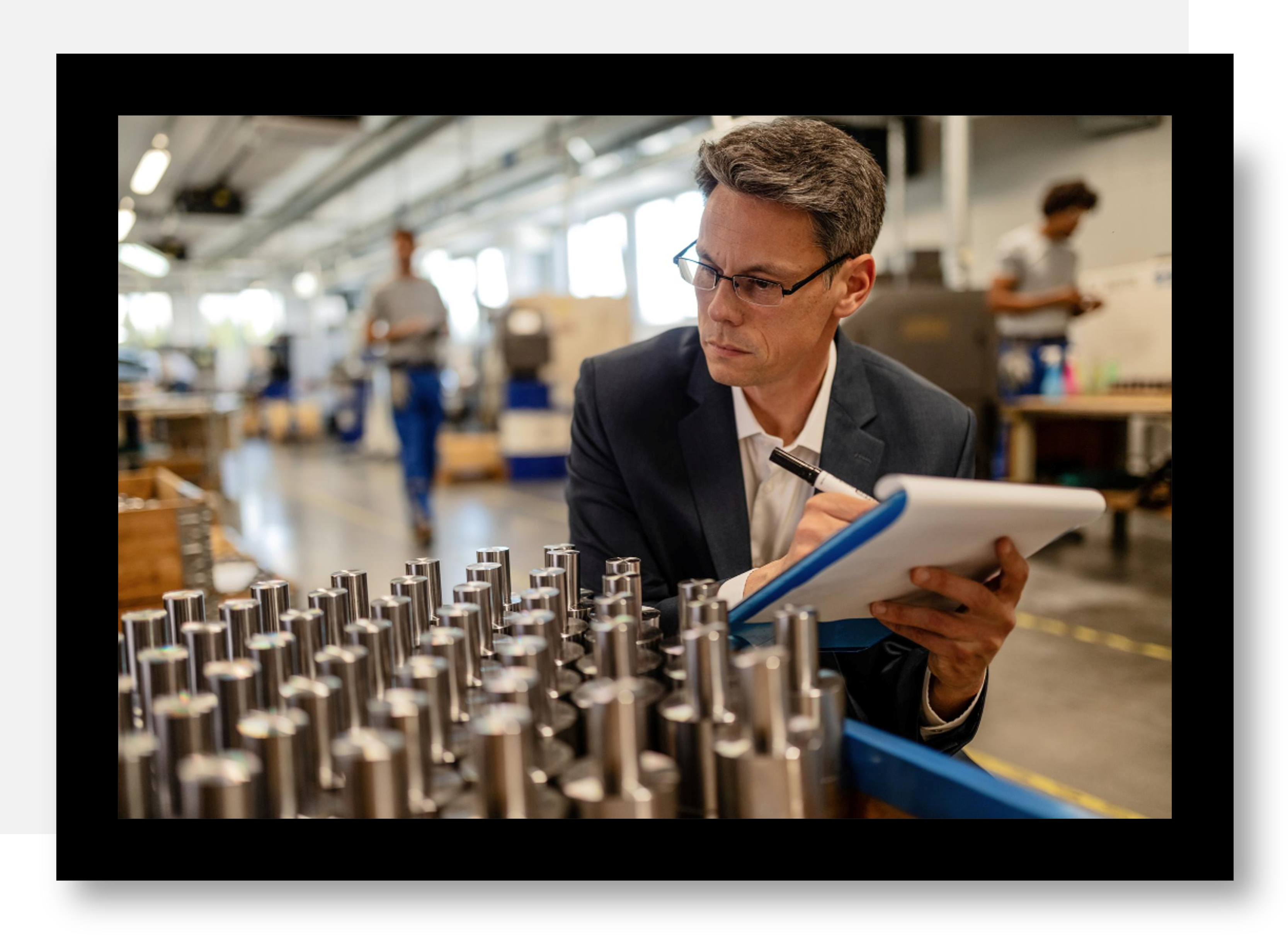

We help manufacturers to improve inspection accuracy and reduce false positives. Our machine vision services can help to monitor assembly sequences in near real-time, provide feedback to automation systems and operators, increase production line throughput, and cut operating costs. The followings are the application areas we support.

Manufacturers are dedicated to identifying even the tiniest imperfections in their assembly inspections, conducted at various phases of production. Our models, powered by AI-driven computer vision, enables precise scrutiny of part orientation, presence detection, part dimensions, and angles of part geometries according to strict specifications. This technology empowers manufacturers to swiftly identify incorrect, misplaced, missing, defective, and deformed components with enhanced accuracy and reliability.

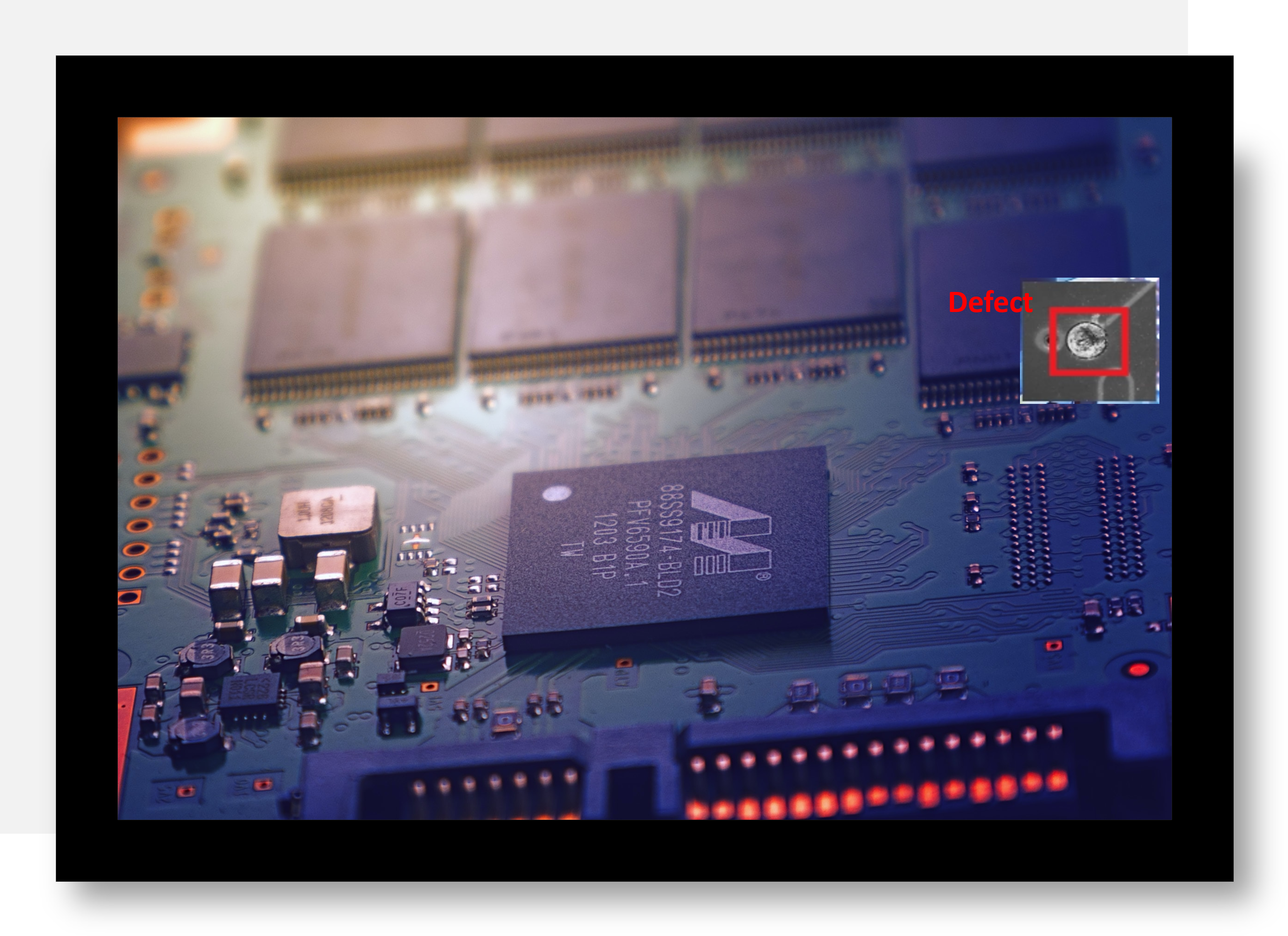

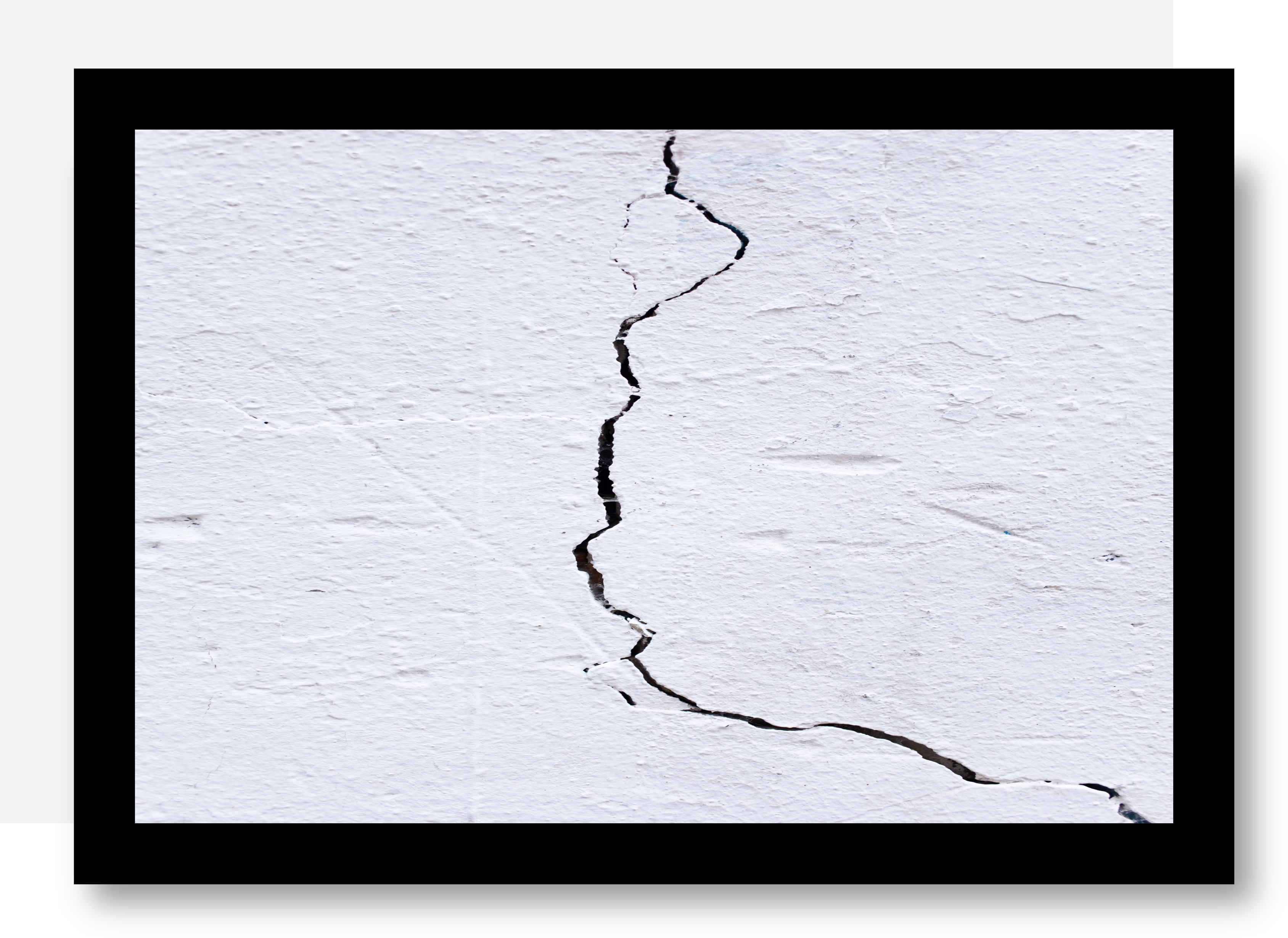

Manual inspections are time-consuming and often yield unreliable results, but our computer vision services offer a streamlined and highly accurate alternative. By automating the inspection process, we can detect defects before products exit the manufacturing facility. Our services enable manufacturers to train models that can efficiently identify, classify, and pinpoint multiple types of defects at a rapid pace and on a large scale.

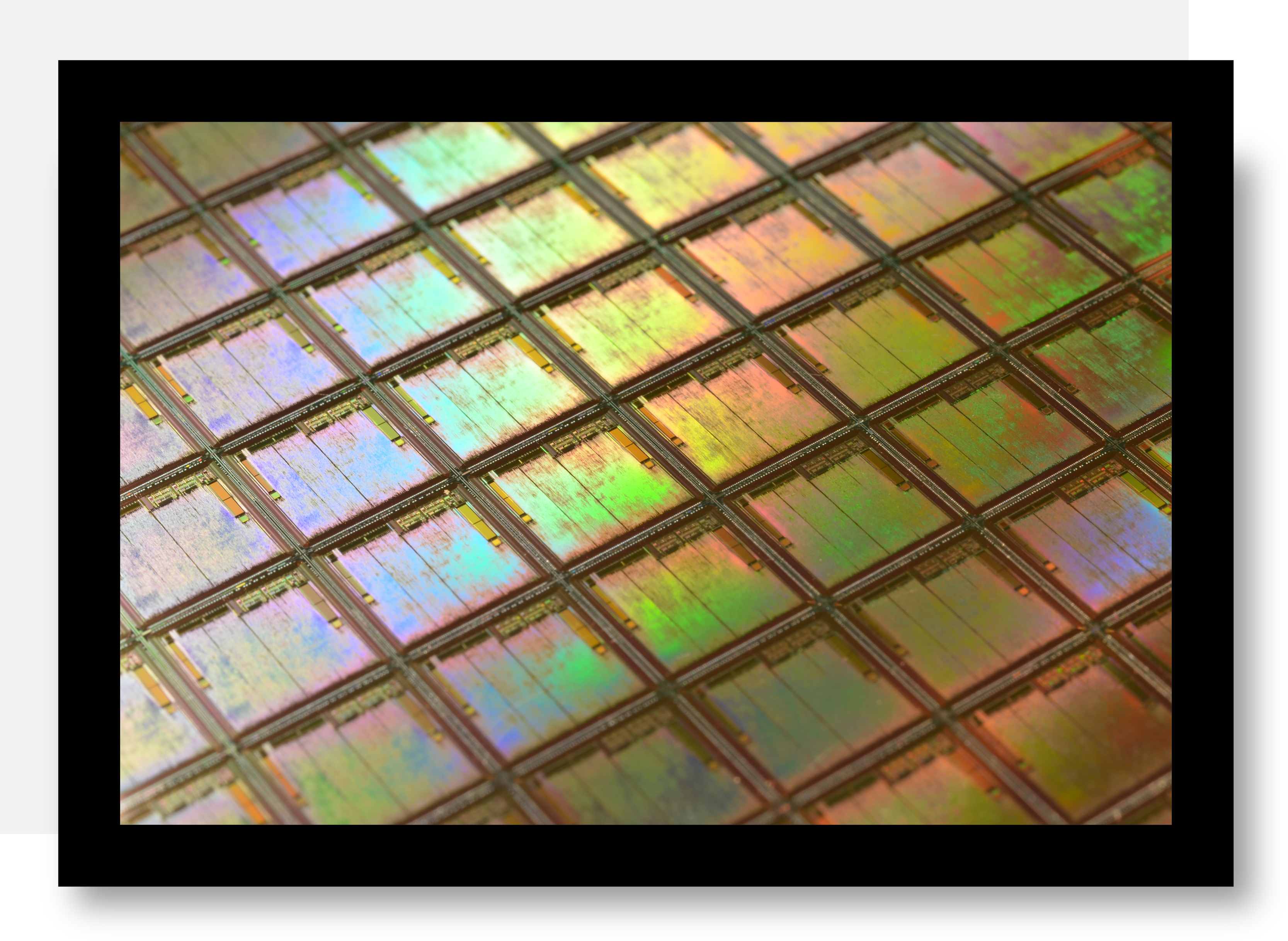

Wafer inspection involves inspecting each individual layer of a semiconductor wafer for defects before applying the next layer. Defects can include cracks, scratches, missing components, and edge defects. While machine vision technology provides a means for automated visual inspection, the range of potential defects on a wafer is significant. Our deep learning models trained on a set of images can help identify defects and anomalies with increased accuracy.

Electronics manufacturers must visually inspect integrated circuits (ICs) for defects such as bent, missing, or twisted pins. Missing catching these defects can lead to failures, reworks, or worst outcomes for safety crititcal applications. Machine vision systems can inspect for such errors, but the large number of defect types poses a challenge to the performance of such rules-based systems. Deep learning models can help classify defects that traditional systems cannot and result in improved performance in terms of both time and accuracy.

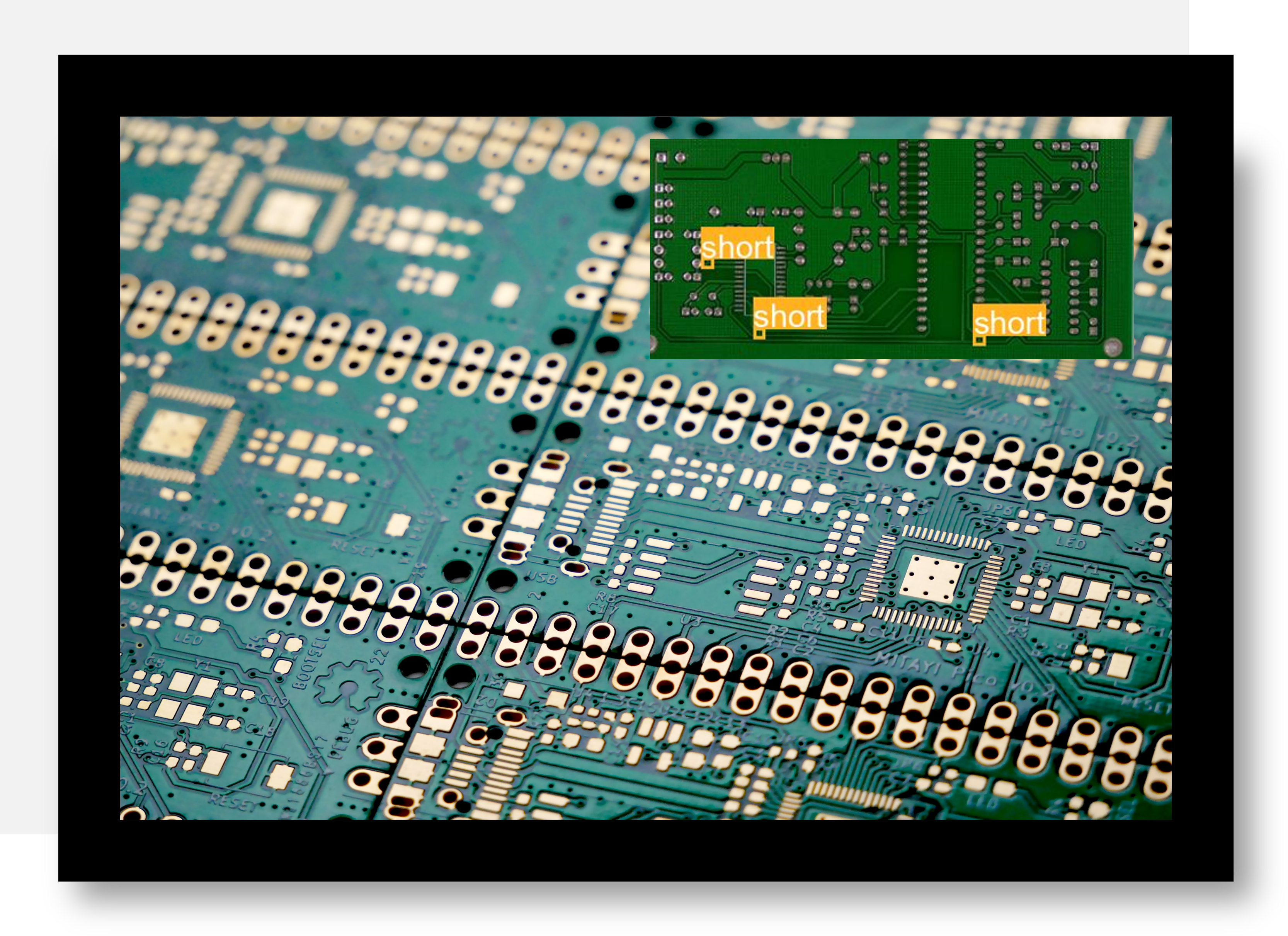

Some of the most common inspection applications in electronics manufacturing involve printed circuit board (PCB) inspection. PCB production involves several different assembly steps with small components. Conducting failure mode and effects analysis for each wafer, pin, joint, and environment change is a staggering task, and rules-based machine vision makes defining defects difficult or impossible. Deep learning models allows manufacturers to detect and classify these defects more efficiently.

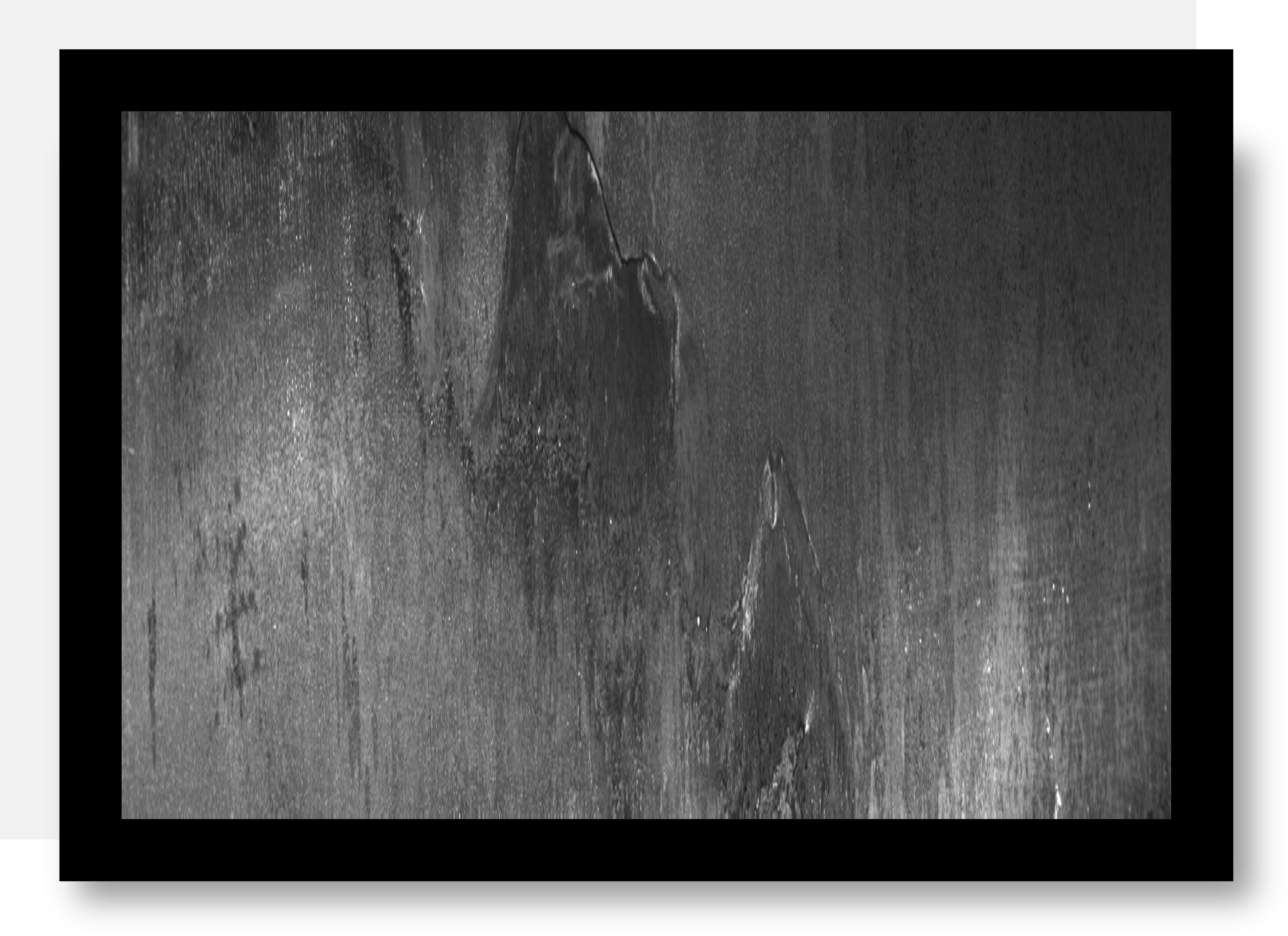

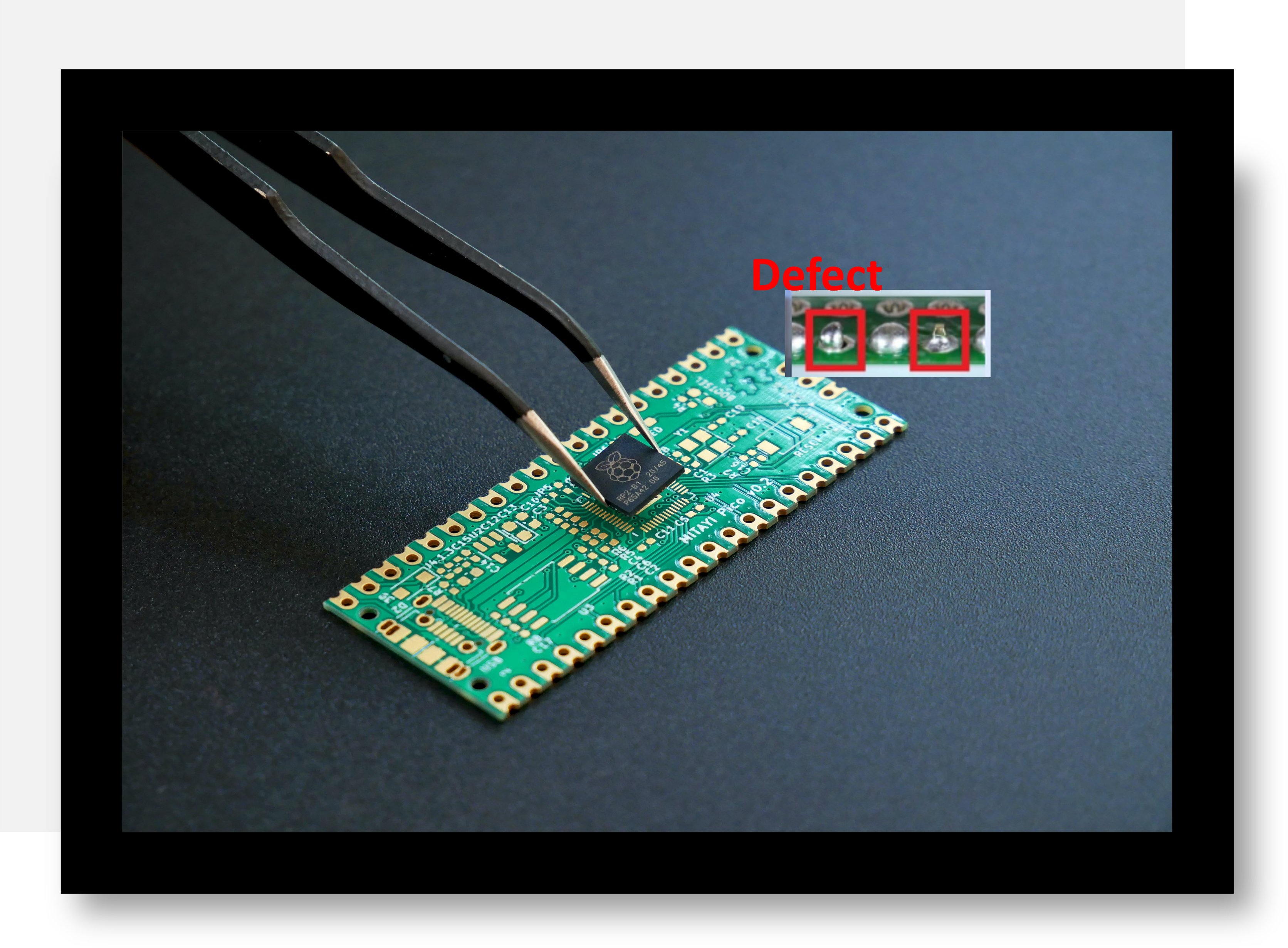

Welding and soldering metal pieces together in electronics manufacturing often produces slight variations in each weld. Machine vision systems might capture acceptable variations as shadows or reflections, and read them as defects. Deep learning models can help differentiate between actual defects and image variations more efficiently and can drastically increase the validation phase. This not only reduces false alarms but also streamlines the manufacturing process, minimizing rework and maximizing production efficiency.

Solar panel inspection involves visually checking several layers of photovoltaic cells within a panel. If defective solar panels make it to a customer, the product becomes less efficient over time and may eventually break. Defects include cracks, scratches, and bubbles. Manufacturers often deploy visible and nonvisible imaging techniques to identify these flaws. However, rules-based techniques may struggle with identifying acceptable variations or with the sheer number of defects that could be present.

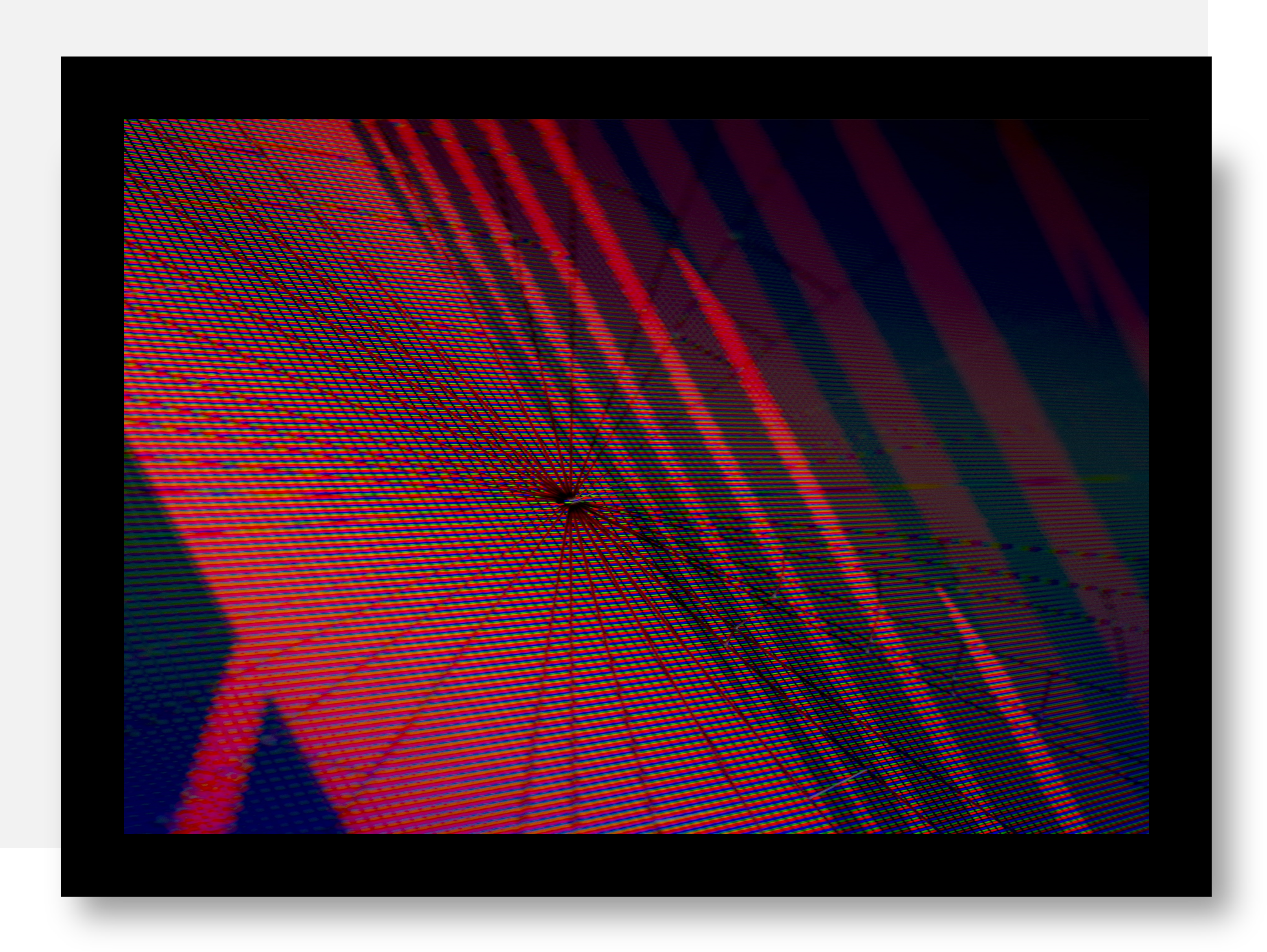

An essential quality-assurance step involves inspecting the surfaces of fully assembled electronic devices, like smartphone displays and keyboards. During manufacturing, various flaws may emerge, such as blemishes or irregularities, which are challenging to identify using conventional machine vision methods. Deep learning moedls, trained on images of both faulty and flawless items, can deliver more dependable pass/fail outcomes.

Producers are required to scrutinize electronic screens like televisions and monitors to detect flaws and blemishes, such as dust particles, scratches, and fractures. These anomalies can prove challenging to identify using rule-based machine vision approaches, but deep learning models, educated on collections of images portraying both faulty and intact items, can provide precise pass/fail assessments. This advanced technology not only enhances the accuracy of inspections but also reduces the likelihood of false positives.

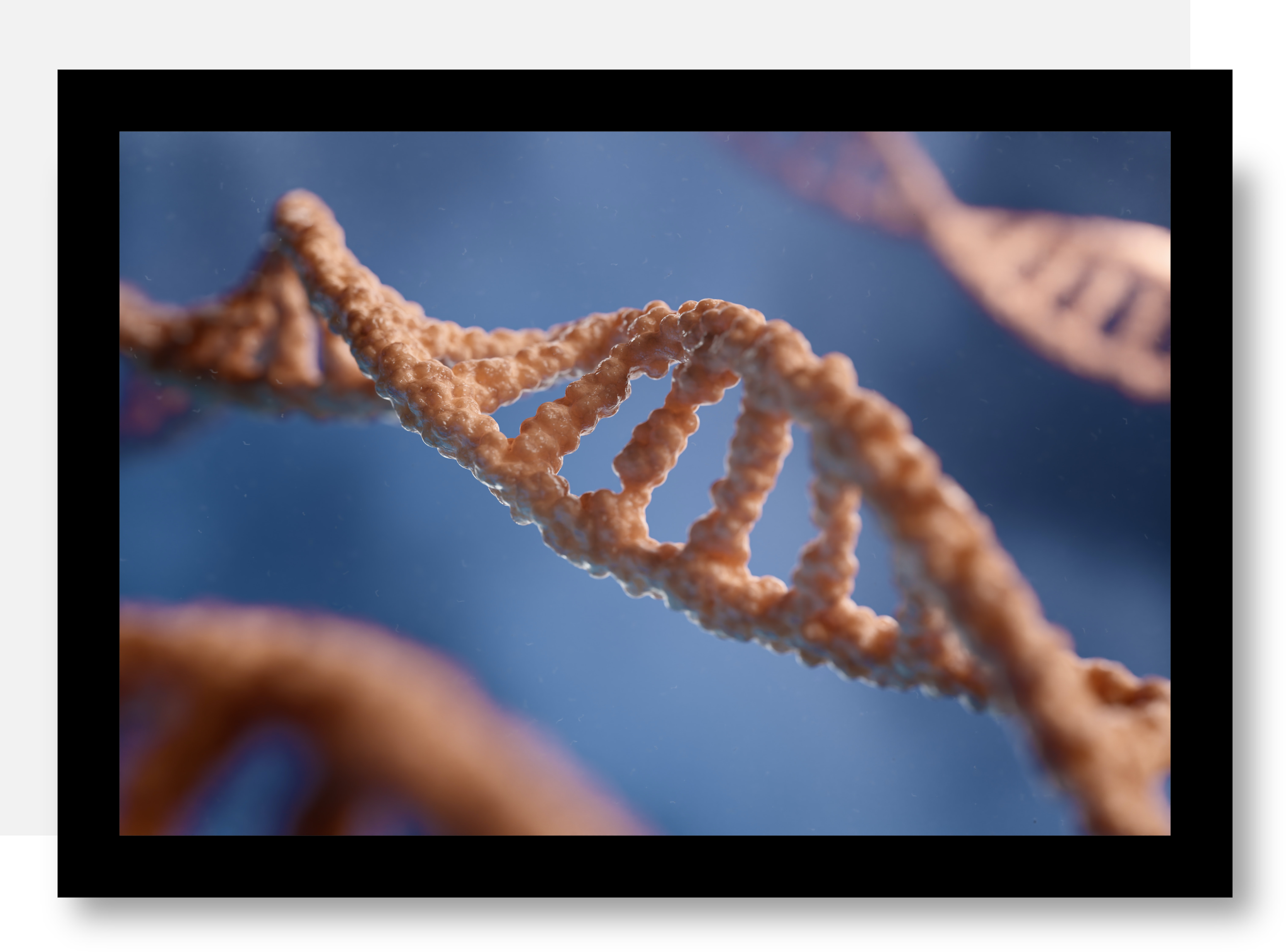

Our machine vision models offer a versatile solution for expediting image recognition across diverse biomedical research applications, including disease detection, drug discovery research, component sorting, and pattern recognition. They not only help identifies autosomal DNA charts and flags out-of-range clinical data but also handles numerous other visual tasks efficiently, both in high-volume and large-scale settings. By enhancing image recognition capabilities, Our models empower researchers to accelerate their work and advance critical biomedical studies.

Our deep learning models revolutionizes traffic surveillance by converting camera image feeds into actionable, data-driven insights on vehicle flow and driver behavior. This AI-powered computer vision system offers real-time car count , flow volume analysis, and more. Moreover, it can be customized to identify various vehicle types and specific features, providing a comprehensive solution for advanced traffic monitoring and management.

Surface defect detection, typically carried out by manual inspectors, plays a crucial role in ensuring that vehicles do not exit the factory with imperfections. This process is essential for upholding the company's reputation and maintaining customer satisfaction. By identifying and rectifying defects before vehicles reach the market, the company can deliver high-quality products and bolster its standing in the automotive industry.

Public agencies can harness the power of real-time object and anomaly detection through the our deep learning models by customizing it to identify specific items and behaviors. This capability extends to recognizing anomalies that may pose safety risks. Our AI-driven recognition can swiftly pinpoint safety concerns, facilitating timely interventions to prevent potential escalations and ensure the safety and well-being of the public.

Visual inspection helps ensure that products meet the required quality standards and specifications. It allows for the detection of defects, irregularities, or deviations in product appearance, which may affect functionality or safety

Our visual inspection models can become an integral part of process control. It allows for real-time monitoring of manufacturing processes, helping companies maintain consistency and quality throughout production.

Many industries are subject to strict regulations and standards. Our visual inspection models help companies ensure that their products comply with these regulations and avoid legal and financial penalties.

Our visual inspection models can identify issues at an early stage of production, preventing the production of defective products and reducing waste and rework costs.

In industries such as aerospace, automotive, and healthcare, our visual inspection models can play a vital role in identifying any visible flaws or faults that could compromise the safety.

Detecting defects early in the production process can significantly reduce the cost of rework, scrap, and warranty claims which can be gauranted by our computer vision models.

Out automated visual inspection systems can operate at high speeds and with great precision, increasing production efficiency and reducing the need for manual labor.

High-quality, visually appealing products are more likely to satisfy customers. Our models helps maintain a positive brand image and customer loyalty.

Our visual inspection models can work 24/7, providing continuous monitoring and freeing up human resources for other valuable tasks.